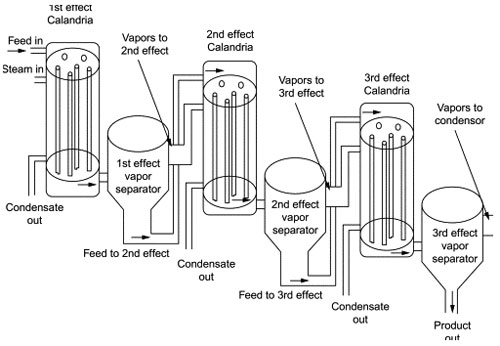

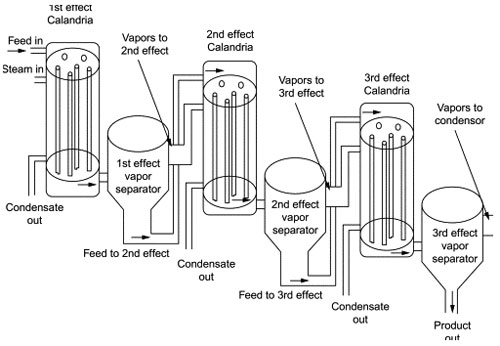

Multiple Effect Evaporator

It is a type of heat transfer equipment that uses natural convection or forced convection for the transfer of heat.

Steam is used in the evaporator to heat up a solution containing a desired product. When the solution is heated, the water in it is converted into vapour, which is condensed.

The vaporized concentrated solution is then removed or fed into a second evaporator for a further concentration process.